Powerful XC-wing with a canopy weight from 3.6 kg

Combines sportiness of the C-Class with maximum flight comfort

Innovative construction for a easy handling and stability

light weight

sporty

versatile

Who is the HELIOS RS for?

You dream of epic XC flights off the beaten track? You want to explore unknown terrain with light luggage, or simply go relaxed “on the trail” with a focus on the flying experience?

Then the predictable and reliable XC all-rounder Helios RS is exactly the right partner for your adventures! Due to its simplicity, the Helios RS is also ideal for newcomers from the C-class.

FEATURES

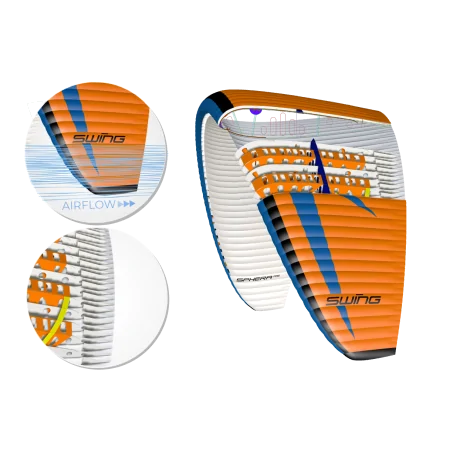

RAST - for maximum control

On paragliders with RAST® the canopy is divided into different internal pressurised sections by one or more fabric panels, some with valves running crossways to the direction of flight. This makes it possible to influence the air flows within the canopy.

With RAST, the air equalisation flows within the paraglider canopy can be regulated through defined openings. This applies both when filling,(during take-off) and when emptying. In the case of pressure loss, e.g. caused by canopy collapse in turbulent air, the relative internal pressure of the CORE section increases, while the BUFFER section absorbs the introduced energy by deformation.

Furthermore, RAST can be used as an additional support to the leading and trailing edge, which has a positive effect on flight comfort. As RAST connects the ribs over the entire profile height, the construction has a stiffening effect and reinforcements and/or stiffening elements can be saved or even completely replaced by this special construction method.

In the Helios RS, RAST® has been optimized for the following properties:

Maximum control and stability in turbulence

High canopy stiffness with reduced internal volume

Easy launch behavior

Intelligent lightweight design

This new approach for the design of the HELIOSRS uses far fewer internal components.

This was possible because of the innovative way we combined the use of reinforcement tape and diagonal rib-tapes, with an optimised line geometry and the positioning of RAST.

An increased number of line attachment points in combination with very short top lines means that the HELIOSRS needs only 5cm wide diagonal rib-tapes, and still the canopy maintains all of its rigidity.

We were able to do away completely with the C level reinforcement wires.

This concept has the following advantages:

reduction in weight and pack size

greater stability in turbulent conditions

easier handling on the ground and when packing up

Nitinol foils, the material with the shape memory as nose reinforcement.

Nitinol is a high-strength, temperature- and corrosion-resistant shape memory alloy. The name Nitinol is an acronym for Nickel Titanium Naval Ordnance Laboratory.

This material is well-known in medical technology, and for a long time Swing has been using it as leading edge reinforcement in paraglider design, one of the first paraglider manufacturers to do so. For the HELIOSRS, the Nitinol reinforcements are inserted into nylon tubes. This meant that the cross-sectional area (and thus the contact area for the top surface material) could be increased without having to forego the positive features of the memory alloy (bend-resistance, length and dimensional stability).

Mini ribs with 3D shaping and internal stiching

Ballooning on the trailing edge has a considerable influence on a paraglider’s control pressure and handling. That’s why, with the TWIN RS 2, ballooning in this area was reduced to a minimum using 3D shaping, in addition to the tried and tested mini ribs. The trick here is that the mini ribs have internal stitching on the top surface so that none of the threads can get caught up on the ground and pulled out, even when launching in difficult terrain.

3D shaping - for optimized aerodynamisc

The specific control of tensions by 3D shaping at the leading edge in the upper sail has become a standard in paraglider construction in order to make the flow-relevant areas as wrinkle-free as possible. Depending on the model, 3D shaping is either single or double.

We have enhanced the standard 3D shaping with additional 3D shaping at the trailing edge to optimize the aerodynamic efficiency of the miniribs.

C-steering, the SWING C-Bridge for more pitch control

In the HELIOSRS, we replaced our proven C-bridge for pitch control by a rocker linking the C2 riser with the B riser.

Thus, by pulling down the C-riser during accelerated flight, the pilot has a much more effective and efficient control over the angle of attack, without having to ease up on the speed bar.

Performance-focussed pilots are thereby able to actively control and steer the HELIOSRS at speed.

For changes to direction or emergency steering, we recommend steering independently using the C1 riser.

Technical Data

| SIZE | XS | S | M | L |

| LTF/CEN Certification | C | C | C | C |

| Accepted weight range (kg) Min/Max incl. Equipment | 70-85 | 80-95 | 85-105 | 100-117 | | | | |

| Cells | 60 | 60 | 60 | 60 | | |

| wing area (m²) | 20,8 | 22,4 | 24.9 | 27 |

| wing area projected (m²) | 18 | 19,4 | 21,6 | 23,4 |

| wing span (m) | 11,2 | 11,7 | 12,3 | 12,9 |

| projected wing span (m) | 9,1 | 9,4 | 10 | 10,4 |

| Aspect ratio | 6,1 | 6,1 | 6,1 | 6,1 |

Projected aspect ratio Glider weight (kg) Min. sink rate (m/s)* Max. speed (km/h) * Trim speed (km/h) * | 4,6 3,6 1 54±2 40±1 | 4,6 3,9 1 54±2 40±1 | 4,6 4,1 1 54±2 40±1 | 4,6 4,4 1 54±2 40±1 |